Technology

The Technology You Need,

the Partner You Deserve

Technology

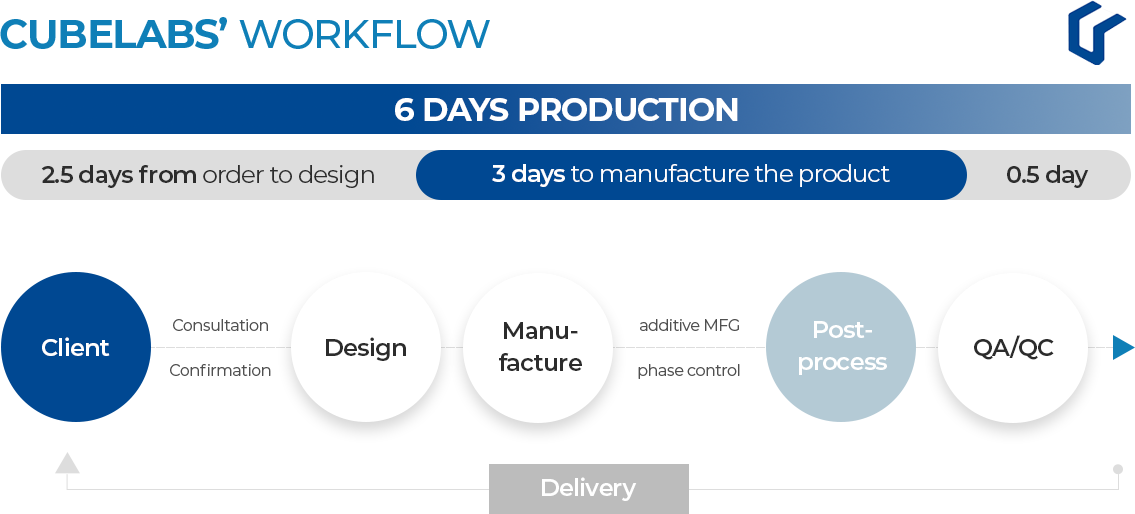

It's easier and faster than expected.

*Delivery period may vary depending on order conditions such as product interpretation / design /size etc.

This streamlined and precise manufacturing process ensures that each Titanium Customized Implant is crafted with meticulous attention to detail, offering optimal outcomes and enhancing the quality of life for our patients.

Our Manufacturing Technology

At Cubelabs, we employ a meticulously structured and efficient manufacturing process to ensure that each Titanium Customized Implant is tailored precisely to meet the unique needs of our patients. Here’s a comprehensive overview of our process:

1. Consultation and Design

Initial Consultation and Medical Review:

Consultation begins with detailed medical reports, including high-resolution CT or MRI scans (with a resolution of under 1mm).These data provide the foundational data necessary for customizing the implant.

3D Virtual Design:

- Doctor Confirmation:Using advanced 3D virtual design and simulation software, we collaborate closely with the attending surgeon to specify the exact surgical requirements and design parameters.

To ensure that the implant will meet the precise anatomical and functional needs of the patient. - Design Process:This consultation and design phase typically takes between 1~2.5 days from the initial order to final design confirmation.

2. Manufacturing

ISO Certified GMP Facility:

- Additive Manufacturing:our ISO-certified GMP facility begin to built the implant layer-by-layer, incorporating a porous and lattice structure for bone integration and mimics the natural strength and durability of the implant material.

- Control Phase:Stringent measures monitor and ensure consistency and precision throughout the process.

- Post-Processing:Additional steps refine the implant's surface and prepare it for implantation.

Manufacturing Facility

Quality Control and Delivery

Quality Assurance and Control

Final Inspection

A rigorous Quality Assurance (QA) and Quality Control (QC) program is conducted to ensure the implant meets all specified standards and requirements.

Certification

Our QA/QC process is ISO certified, guaranteeing that every implant we produce meets the highest quality and safety standards.

Shipping and Delivery:

Preparation for Shipment

Once the implant has passed all quality checks,

it is meticulously packaged and prepared for shipment.

ON-TIME Delivery

The finished product is then shipped to the specified location, ready for surgical use.